The Art and Craft of Sign Board Manufacturing

Sign boards are more than just tools for communication; they are an essential part of branding, guiding customers, and creating memorable experiences. The manufacturing of sign boards involves a blend of artistry, technology, and precision. In this article, we delve into the intricate process of sign board manufacturing, showcasing the steps involved and the materials used, accompanied by illustrative images.

1. Conceptualization and Design

The first step in sign board manufacturing is the conceptualization and design phase. This involves understanding the client’s requirements, the message to be conveyed, and the environment in which the sign board will be placed. Designers use advanced software to create detailed mockups, ensuring the design aligns with the brand’s identity.

Image: A designer working on a computer, creating a sign board design.

2. Material Selection

Choosing the right materials is crucial for the durability and aesthetics of the sign board. Common materials include:

- Acrylic: Known for its clarity and versatility.

- Aluminum: Lightweight and weather-resistant, ideal for outdoor signs.

- PVC: Durable and cost-effective, suitable for various applications.

- Wood: Offers a classic, rustic look.

Image: Samples of different materials like acrylic sheets, aluminum panels, PVC boards, and wooden planks.

3. Cutting and Shaping

Once the design and materials are finalized, the next step is cutting and shaping the materials. This process requires precision and is often carried out using CNC (Computer Numerical Control) machines, laser cutters, or manual tools, depending on the complexity and material.

Image: A CNC machine cutting an acrylic sheet into the desired shape.

4. Printing and Painting

For sign boards that include graphics, logos, or text, printing or painting is the next step. UV printers are commonly used for high-quality, weather-resistant prints. Alternatively, vinyl graphics may be applied to the surface. Painting involves using durable, fade-resistant paints to ensure longevity.

Image: A UV printer printing vibrant graphics onto a sign board.

5. Assembly

After the individual components are prepared, they are assembled. This may involve attaching letters to a backing board, combining different layers, or adding illumination elements. Precision is key to ensuring that all parts fit perfectly and the final product is robust.

Image: Technicians assembling the different components of a sign board.

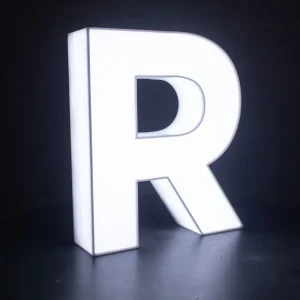

6. Illumination

Illuminated sign boards are popular for their visibility and impact. LED lights are the preferred choice due to their energy efficiency and long lifespan. The lights are carefully integrated into the design, whether as backlighting, edge lighting, or through-lit letters.

Image: An illuminated sign board with LED backlighting.

7. Quality Control

Quality control is a vital step to ensure the sign board meets all specifications and standards. This includes checking the structural integrity, verifying the accuracy of colors and graphics, and ensuring all electrical components function correctly.

Image: A quality control inspector examining a finished sign board.

8. Installation

The final step is the installation of the sign board. Professional installers ensure that the sign is securely mounted and positioned for maximum visibility and impact. They also check that any electrical connections are safe and compliant with regulations.

Image: Technicians installing a sign board on the exterior of a building.

Conclusion

The manufacturing of sign boards is a meticulous process that combines creativity, technology, and craftsmanship. From the initial design to the final installation, each step is essential to creating a sign that is not only functional but also a reflection of the brand it represents. By understanding the detailed process and the importance of each phase, businesses can better appreciate the value of a well-made sign board.

For more information on sign board manufacturing or to get started on your custom sign, visit Signage Mumbai.

-

2D Acrylic Letter

₹30.00 -

3D Acrylic Letter (Non-lit)

₹50.00 -

3D Building Signs

Original price was: ₹12,000.00.₹11,499.00Current price is: ₹11,499.00. -

3D LED Acrylic Letter

₹190.00 -

3D LED Acrylic Letter with ACP

₹200.00 -

A-Board Display Stand

Original price was: ₹3,200.00.₹2,999.00Current price is: ₹2,999.00.